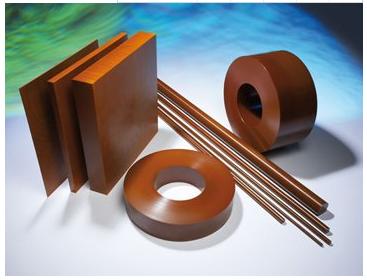

Nylon rod is an important engineering plastic, which can replace the wear-resistant parts of mechanical equipment and copper and alloy as the wear-resistant parts of equipment. It has the characteristics of good toughness, strong wear resistance, oil resistance, earthquake resistance, good tensile and bending strength, small water absorption and good dimensional stability, so it is used to process all kinds of wear-resistant high-strength parts. It is suitable for making wear-resistant parts, transmission structural parts, household appliance parts, automobile manufacturing parts, screw rod, textile machinery parts, chemical machinery parts and chemical equipment. Such as turbine, gear, bearing, impeller, crank, instrument panel, drive shaft, valve, blade, screw rod, high-pressure washer, screw, nut, sealing ring, shuttle, sleeve, shaft sleeve connector, etc.

Generally speaking, the nylon rod made of nylon 1010 or MC nylon is more wear-resistant, and the most wear-resistant is the nylon rod added with wear-resistant modifier. A kind of nylon 1010 modified plastics is prepared by mixing nylon 1010 resin as (bonding) base material, adding various antifriction materials in extruder. Compared with pure nylon 1010 resin, it has lower friction coefficient, higher PV value, better friction and wear resistance and better self-lubrication.