Compliant materials solutions for the food industry

Compliant materials solutions for the food industry

The production of food safety plastics that meet the strict requirements of FDA and European food contact regulations is a key requirement for thermoplastic processing operators in this field. In addition to acting as the agent of standard thermoplastic engineering plastic product series, dotma can also provide special plastic products that can contact with food to meet the specific requirements of food technology in terms of safety and performance.

Because of its light weight and easy processing characteristics, food grade materials can replace metals and be used in various mechanical processing such as meat, fish and poultry processing, dairy products, baked goods and candy production. Rolex’s food contact materials promote production and improve the speed and safety of the manufacturing process. In addition, when metal detectability is required, our special metal detectable plastics and blue optical detectable plastics for the food industry can replace traditional plastics, so as to improve performance and reduce cost.

Processable plastics for food industry

Pom-c natural color

Pom-c pure material has balanced physical properties, which is not available in other thermoplastics. This engineering plastic is widely used in various industries. The key properties of pom-c pure material include high mechanical strength and high stiffness, excellent wear resistance, low moisture absorption and excellent dimensional stability.

Pom-c blue

The bright blue of pom-c co formaldehyde material is easy to identify. The use of this material in food production can facilitate the identification of foreign particles in food through optical detection equipment. This versatile engineering material meets the requirements of various industries and has the unique performance characteristics inherent in pom-c materials.

Peek pure material

Polyether ether ketone (PEEK) - Victrex ® Peek 450g is a high-performance semi crystalline high-temperature plastic produced as a base material. The material has excellent wear resistance and excellent mechanical properties even under thermal load. Excellent chemical resistance and high operating temperature (up to 260 ° C)

Polyamid6

PA 6 material is the most common extruded polyamide, which combines all the typical performance characteristics of this material group. It has good damping capacity and excellent impact strength and toughness even at low temperature. In addition, it also has good wear resistance, especially when the surface of mating parts is rough.

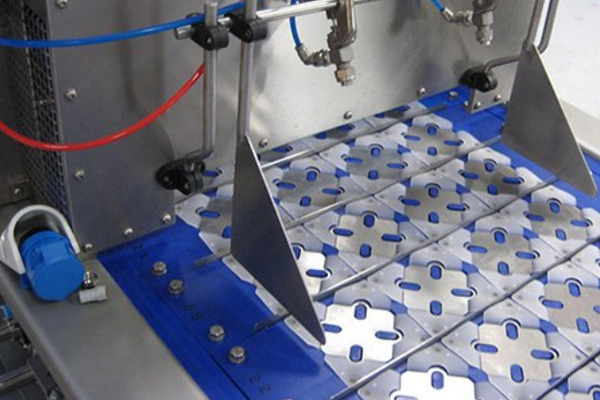

Use a food scraper made of detectable pom-c

In the food industry, most filling machines use scrapers to ensure the continuous flow of food such as meat or sausage meat. For this application, the scraper used is made of POM ah material, a food grade polyoxymethylene material.

Baking machine equipment is popularized, safe and reliable

While manufacturing standard machines, form & frys can provide customized equipment for various specific products. They used POM ah blue material in the machine. Because the material has a bright blue, it is safer at every stage of food processing. It not only promotes the product brand, but also ensures that any plastic fragments can be quickly detected in the production process.