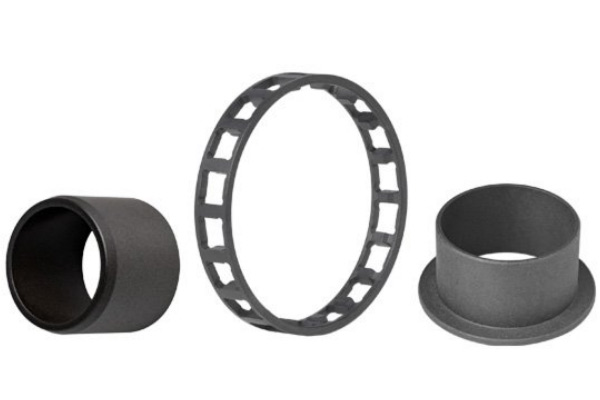

Plastic solutions for Mechanical Engineering

Plastic solutions for Mechanical Engineering

In the production process of mobile phone production line and automobile production line, the consumption of materials is caused by wear, corrosive chemical medium, speed or temperature in some cases. We suggest new materials to make the operation of the production line more stable, lasting and efficient.

PLASTICS FOR MECHANICAL ENGINEERIN

PEEK natural

Polyetheretherketone (PEEK) - PEEK natural is a high performance, high temperature, semi-crystalline thermoplastic

PA 66 natural

Polyamide 66 has good rigidity, hardness, abrasion resistance and thermal dimensional stability. In addition, nylon 66 has outstanding wear resistance and low frictional

POM-H natural

POM-H is a homopolymer acetal that is manufactured by Ensinger under the tradename POMH natural. This homopolymer acetal has exceptional sliding characteristics and good wear resistance properties.

HPV-PEEK natural

PEEK HPV black is a modified PEEK polymer with 10% each of PTFE, graphite, and carbon fibre. That makes PEEK-HPV an ultra high performance plastic material

Composite robotic arm

In high speed moving components, saving weight is crucial to reducing inertia and improving efficiency. In this case study, a composite robotic arm used for high-speed picking and handling Delta Robots was enhanced by replacing a metal insert with PEEK natural high performance thermoplastic material.

Safe braking with modified PEEK

In modern passenger aircraft, the use of electric braking systems is considered to reduce maintenance and improve reliability.The engineering challenges to manufacturing these new systems require the Polymers used to have greater wear and load-bearing properties. These properties are met by TECAPEEK PVX.