Plastic solutions for Aerospace

Plastic solutions for Aerospace

The excellent performance of high-performance engineering plastics provided by Rolex can meet the technical requirements of many systems and subsystems used in today’s ultra modern composite aircraft. The fuel saving and low emission aircraft made of light materials has obvious advantages, and the components have a longer service life. In addition, R ö chling’s aerospace materials are not affected by corrosion in the aviation operating environment.

Machinable plastics for Aerospace

Pure peek

Polyether ether ketone (PEEK) - Victrex ® Peek 450g is a high-performance semi crystalline high-temperature plastic produced as a base material. The material has excellent wear resistance and excellent mechanical properties even under thermal load. Excellent chemical resistance and high operating temperature (up to 260 ° C). Its excellent dimensional stability and high creep stability make PEEK material suitable for the most complex machined parts.

Polyamide 66 profile

PA66 pure material has good stiffness, hardness and thermal dimensional stability. In addition, nylon 66 has excellent wear resistance and low friction properties. It also has excellent temperature, chemical resistance and impact properties. When using PA 66 material, it should be noted that it has a tendency to absorb moisture, which may affect the dimensional stability.

Delrin (pom-h) profile

Pom-h homoformaldehyde has excellent sliding property and good wear resistance.

Compared with pom-c, pom-h material has higher density, hardness and strength due to its higher crystallinity. In addition, pom-h material has good electrical insulation and excellent processing characteristics.

Pure PTFE profile

PTFE is one of the most commonly used and important fluoroplastics, which is widely used in various application fields. It is a common material in sliding applications, especially in the environment where components need to withstand chemical stress.

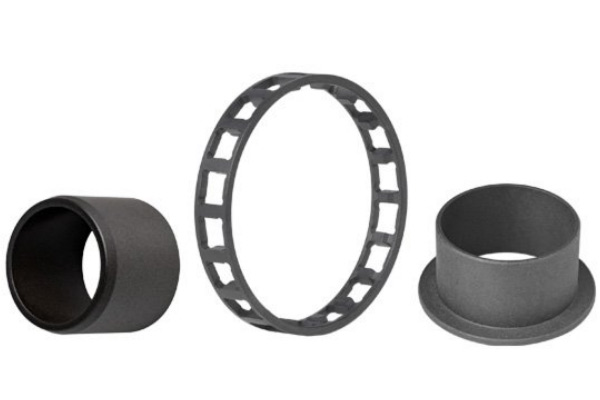

Economical grease plug in landing gear

During aircraft landing and ground operation, the aircraft landing gear needs to support the weight of the whole aircraft. All connecting braces and connecting columns in the landing gear need lubrication to ensure safe operation. The grease is fixed in these connecting braces and connecting columns through grease plugs made of lom-h material of Lloyd’s collar.

Braking system made of modified peek

Electric braking system will be considered in modern passenger aircraft to reduce maintenance and improve reliability. In order to meet the engineering challenges of manufacturing these new systems, more wear-resistant and load-bearing plastics are required, and peek PVX materials can meet these requirements.